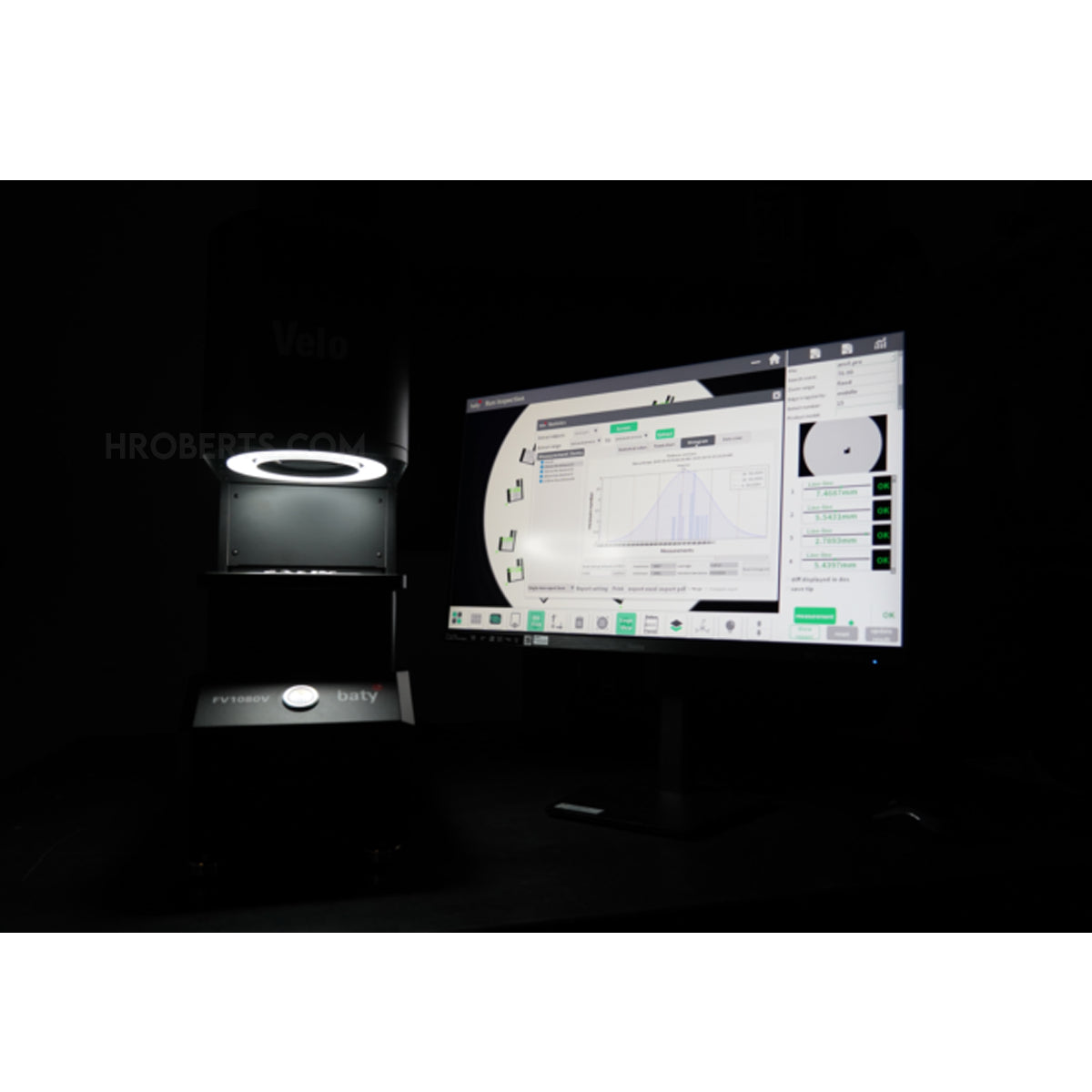

- brand Baty

- range Measuring Range Ø100 x 80

- accuracy ± 3μm

- remarks Max Load 3kg

- repeatability ± 1μm

- lens ø100mm; ø100mm Bi-telecentric lens

- lens ø100mm; ø100mm Bi-telecentric lens

- transmission light Telecentric Parallel Illumination (Green Light)

- surface light Ring lighting (white light)

The Baty Velo is the latest addition to the Baty Venture FV series of flash measurement systems. This a lightweight, compact, and powerful entry-level machine designed for fast, precise, non-contact measurement.

Unique on the market, the NEW Baty Velo offers full measurement and reporting functionality with high-end telecentric optics and lighting to achieve 3 um accuracy on 100's of measurements in a single second.

The Baty Velo is streamlined for portability and ease of use, making it ideal for high-volume, low-value component inspection. Offering advanced measurement capability at accessible pricing, the Baty Velo is a globally exclusive model, available only through Bowers Group and our trusted partners.

Compact & Lightweight

- Small footprint and portable build

- Easily moved from cell to cell

- Perfect for desktop use in tight production spaces

- Automatic part grading for matched assembly operations

High-Speed Measurement

- Fixed 100mm x 80mm field of view

- Delivers hundreds of measurements per second

- Ideal for repeatable inspection cycles of similar parts

- 3μm accuracy

Premium Optics

- Full telecentric backlight for distortion-free imaging

- Single LED ring light for effective surface illumination

- Built-in Auto Focus ensures consistent, clear results

Additional Features

- Simple and intuitive user interface designed with operator in mind.

- Easy-to-use software allows creation of new inspections quickly and easily with minimal experience.

- Dedicated functions for measuring gears, threads, O-rings, and springs.

- CAD Import enables user to compare profiles to CAD model.

- Auto-create complete inspections from an imported .dwg file, including dimensions and tolerance information.

- Easy reporting including on-screen pass / fail classification.

Automatic Inspection Reports

A range of Excel-compatible reports are immediately available after each inspection, providing measurement data for each measurement including a pass / fail classification. Single part reports include a dimensioned image of the part for easy comparison to the drawing.

Batch inspection results are conveniently compiled into a single batch report. Using character recognition, the software automatically detects identification numbers on each part and then lists the measured results against each part number.

SPC data reports are also included as standard, including normal distribution curves and CP / CPK calculations to monitor process capability.