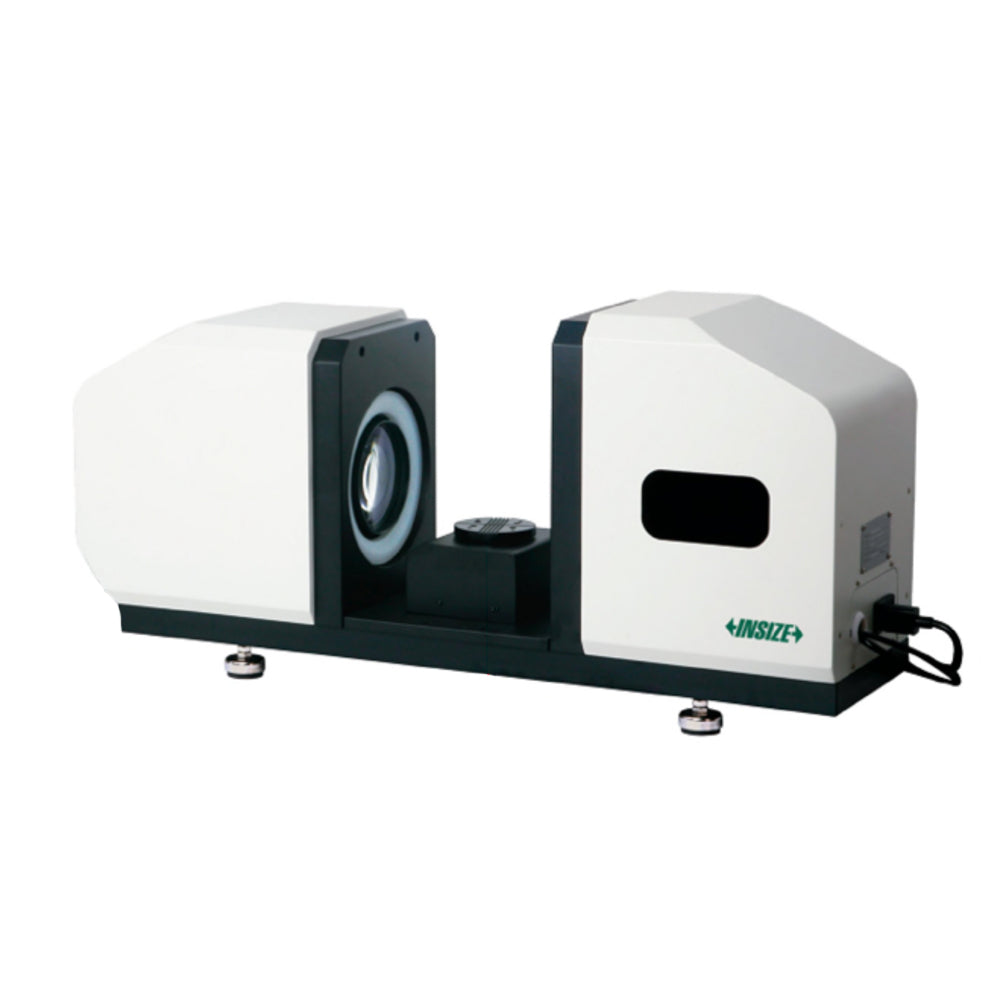

- brand Insize

- type 2D measuement

- range 100x80mm

- lens ø100mm dual Telecentric lens

- lens ø100mm dual Telecentric lens

- transmission light Telecentric Illumination (Green Light)

- surface light High Angle Ring lighting (white light)

The INSIZE QMS-B530 is a high-efficiency, horizontal quick measurement system engineered for rapid and precise inspection of shafts and cylindrical components. Its one-step automatic operation allows users to place one or multiple workpieces on the measurement stage, where the system automatically focuses and measures, eliminating the need for manual adjustments and saving valuable time.

This system is designed to streamline production workflows. By enabling multiple dimensions to be measured in one seamless step, the QMS-B530 significantly boosts throughput, reduces handling time, and minimizes human error. It is ideal for manufacturers who need both speed and accuracy in high-volume production environments.

Automation is at the heart of the QMS-B530’s design. Once the parts are positioned, the machine automatically performs focusing, edge detection, and measurement, delivering consistent, repeatable results. This greatly reduces operator training requirements and ensures uniform results across multiple shifts.

The QMS-B530 is equipped to measure a wide variety of shaft geometries and features, including lengths, diameters, chamfers, grooves, and radii. Its ability to handle multiple workpieces in a single cycle makes it a powerful solution for batch inspection and production line quality control.

The system’s robust construction ensures stability and accuracy even in demanding shop-floor environments. Precision linear guides and a solid frame minimize vibration and ensure measurement consistency. Its compact design allows it to be easily integrated into existing quality control stations.

An advanced optical system delivers clear, distortion-free images, while the integrated lighting setup ensures reliable edge detection across different surface finishes. These features work together to guarantee micron-level accuracy, even when inspecting complex components.

User-friendly software makes it easy to configure inspection routines, automatically generate reports, and store data for process monitoring and traceability. Statistical process control tools are included to help identify trends and maintain consistent product quality over time.

Overall, the INSIZE QMS-B530 is a fast, accurate, and highly automated solution that helps manufacturers maintain tight tolerances, reduce inspection bottlenecks, and increase productivity. It is the perfect choice for quality teams looking to streamline their shaft and cylindrical part inspection process without compromising on precision.